Intertraffic has brought you regular insights into how leading lights and major players across the various industry sectors that make up our exhibitor and delegate database have been coping amid Covid-19 and its unprecedented impact. However, where “new” spheres of smart mobility, such as MaaS and micromobility, have been able to be flexible and nimble, other industries such as infrastructure and construction, have been less able to adapt to the new reality in an agile way due to their core business being hardware and not software.

One such market that has been relentless in its desire to remain at the cutting edge of innovation is the road safety infrastructure sector.We spoke to five protagonists from across Europe whose aforementioned core business is the life- and serious injury-saving practice of designing, manufacturing and implementing crash barriers. The wide-drop in traffic levels has reduced the number of fatal traffic accidents and casualties in several countries. However, has it improved our road safety? Has the continent-wide drop in traffic levels over the past year actually allowed for increased innovation? And what, perhaps more crucially, has been the main impact of the coronavirus on the industry as a whole?

Impact of reduction in traffic on road safety demonstrations

Joseph Marra, a Civil Engineer who manages GDTech’s Crash and Dynamic department in Belgium offers an example of how that aforementioned reduction in traffic affected his company’s work on one particular project.

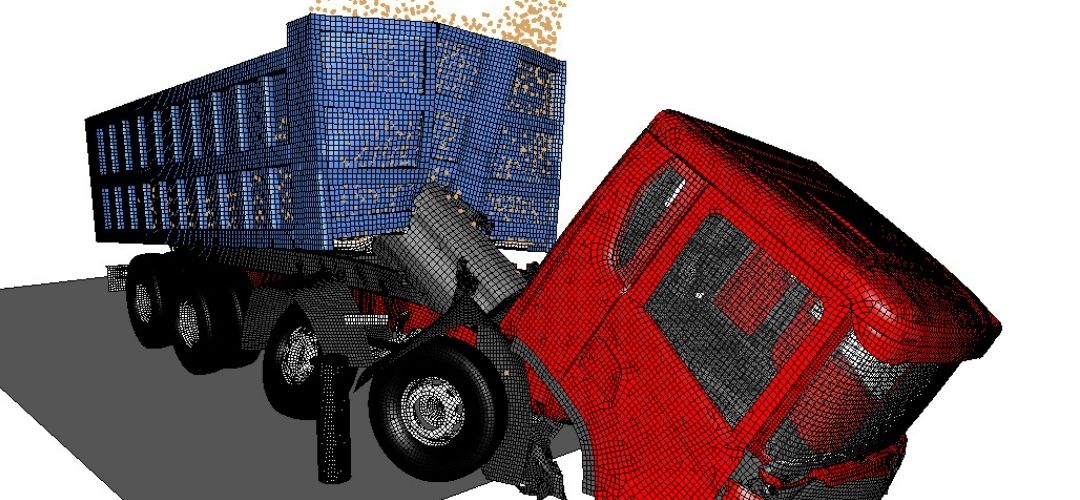

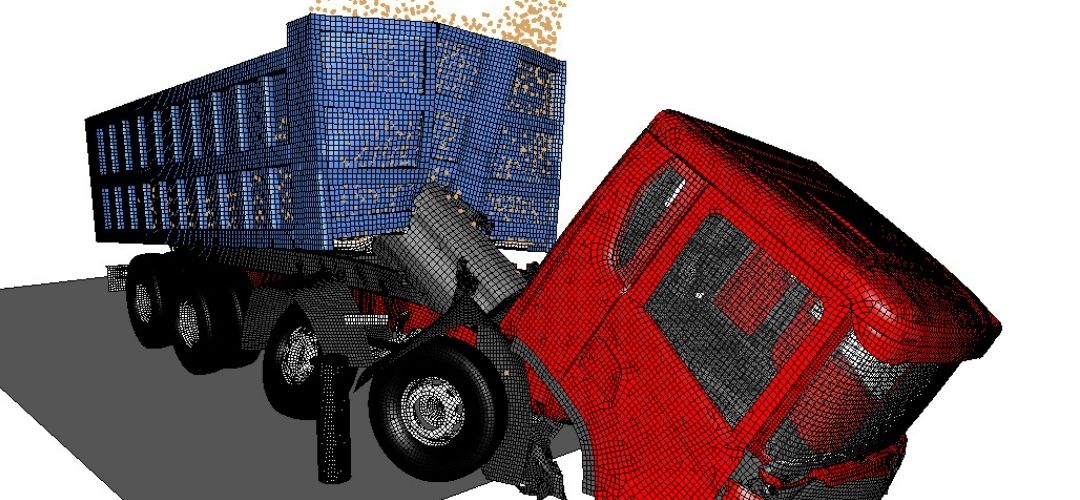

Marra and his team were working on “the development of a bridge barrier to demonstrate how the incorporation of Finite Element Analysis (FEA) into the design process can optimize a solution that is vastly different from the solutions that traditional engineering methodologies would produce” when the first Covid wave struck Europe. “This allowed the engineers to take the necessary time to think, develop and optimize better products and make the best use of simulation,” he insists.

“During the first phase of development, several ideas, in fact more than 100, were tested virtually in order to check if the concepts could have a chance to pass the real crash tests defined by European Standard EN1317. The barrier would need to fulfil aesthetical criteria and would have to deliver the least forces to the bridge deck in the same time. Using finite element simulation was really helpful as several calculations could run in parallel and behaviours could be analysed in depth to spot areas needing reinforcements and others that could be optimized in weight.”

It's fair to say that the pandemic forced GDTech’s hand somewhat but the drastic change in circumstance meant that the company was now almost duty-bound to rely more heavily on simulation.

“A problem concerning too high loads transferred to existing bridge decks was identified and through the iterative use of FEM (Finite Element Method), combined with Eurocodes for structural analysis, a solution was found and optimized that was vastly different to the direction that traditional engineering was leading,” Marra concludes.

“Moreover, the additional benefit of creating advanced models that are validated to EN16303 allows a reuse of those models for other purposes such as the development of modified DOLRE versions or the development of accessories such as transitions. I’m certain that without the use of such advanced tools and methodologies it would have been hard to make the ‘dream’ come true.”

Upholding road safety standards

The EN1317 European standard mentioned by Joseph Marra also plays a vital role in the thinking of Smart Transportation Alliance, among whose members are more than a dozen road restraint system (RRS) manufacturers. The standard was developed within the framework of the Construction Products Directive 89/106/EEC and EN1317-5 serves as a basis for the CE marking of road safety systems such as safety barriers and guardrails, crash cushions, barrier extremities and transitions. The release of EN1317 - after years of research, testing and standardisation efforts – represented a major step ahead for addressing at least 30-40% of road fatalities, which are associated with single-vehicle collisions.

José Papí, President of the STA, a Brussels-based collaborative platform for transportation infrastructure innovation across modes and the Smart City, highlights that today “a number of challenges affect the reliability of the existing EN standards”. Among them, he cites

i) the lack of adaptation of RRS to a new generation of vehicles (e.g. SUVs),

ii) the assimilation of buses (urban use) and coaches (interurban use) in crash-tests,

iii) the lack of comprehensive revision of the existing ‘severity indexes’ (Acceleration Severity Index/Theoretical Head Impact Velocity/Post-impact Head Deceleration) used for conveying the severity of the impact on the vehicle occupants, and

iv) the lack of a common practice across European test-houses when it comes to the type of electronic system used for the recording and computing of test data, the conditions and procedures followed for the measurement activities and other key relevant conditions associated with the crash-test (such as the state of the road surface, its skid resistance, etc).

Taking into consideration the challenges described above, STA calls for a renewed dialogue between road agencies, standardisation bodies, test-houses and industry to adapt EN 1317 to today’s traffic and the requirements of a harmonised Trans-European Transport Network. In Papí's opinion, the alternative, namely inaction, is no longer acceptable and the global “pause” caused by Covid-19 should have proved to be a perfect opportunity to restart that conversation.

“The possibility is there to promote a voluntary ‘excellence’ labelling in the short-term with a view to securing the compliance of EN 1317 (review of the existing certificate emerging from the joint work of the test-house and the certified body), and assess the specific behaviour of RRS products in different conditions and applications. Until the EN 1317 standard is updated, such voluntary labelling could serve to inform road agencies and consumers of the possible safe applications of a product to specific road sections and/or traffic conditions, therefore providing an incentive to manufacturers to supply products with a maximum degree of safety,” he opines. Papí’s passion is palpable, as is his desire for the industry to not look back on the past year as a missed opportunity to adapt EN 1317 to encapsulate the transport world’s altered state.

The mark of excellence

The notion of labelling, as highlighted by Papí, is also highly relevant as this year promises to be a significant one in the road safety infrastructure sector.

2021 will be important for COPRO, AWV and numerous other awarding authorities in the road construction and infrastructure sector, as COPRO’s Ruben Verbeke and Kim Vandenhoeke explain. It will see the further rollout of the long-awaited implementation certification and the accompanying COPRO.EXE quality mark. This is something that has been brought even more sharply into focus by the ramifications of the pandemic, although the diligent efforts of the awarding authorities ensured that, despite the disruption to working life, developments continued apace.

“One of the chosen fields is the installation and repair of road restraint systems. The quality of products may be excellent, but if they are not properly installed and/or maintained, their operation and overall safety is compromised. Through execution certification, we hope to avoid this and make contractors accountable.

Execution certification is a hot topic in the road building and infrastructure sector. The concept was introduced on the initiative of a number of awarding authorities, including AWV. As an independent inspection and certification body, COPRO was given the task of putting all the ideas, wishes and requirements into practice and perfecting the system.

“We were also in demand because we also manage product certification and realise that perfect execution is also necessary to achieve a good end result. Via execution certification, we can complete the circle,” Ruben Verbeke and Kim Vandenhoeke maintain. “In classic public tenders, the price is the decisive criterion for awarding a job and it is not always easy to guarantee the quality. Many awarding authorities therefore needed a different approach. Thanks to execution certification, they can now be sure that contractors are following certain procedures to maintain the required quality level, which will also be monitored by COPRO. Contractors who meet the proposed requirements receive a certificate in the form of the COPRO.EXE seal of approval, which in a sense also functions as a 'quality label'.”

Photo: COPRO

Staying close to our customers: face-to-face crash-testing from home

“The pandemic didn’t interrupt us from innovating and proposing other services to our customers,” says Eloise Champlong, marketing and communications manager at Transpolis, an urban mobility and innovative transport solutions specialist based in St Maurice de Rémens, eastern France.

“In 2020 alone, Transpolis developed new tools in the field of Road Restraint System testing, such as complex machine to carry out push/pull tests; a friction machine in order to characterize friction coefficient, among many others.

The simulation department of Transpolis was also far from idle, as it developed a new range of vehicles.

“Of particular interest is one heavy truck, often in demand by the manufacturers, a 32,000kg 4-axle rigid with a tipper. This new detailed truck can be used to fulfil the requirements of many standards, such as IWA 14-1 (N3F vehicle) and EN1317 (TB71). However, it seems that this new development of vehicle was not challenging the simulation department enough during the pandemic, so they decided to use their dynamic expertise further by becoming specialists in static calculations. This has been a logical continuity to the development of new static tools,” she says proudly. It also seems as though the effects of Covid-19 have brought about other forms of innovation for Transpolis – maintaining close contact with their valued customers, as Champlong explains.

“In any situation, we always support our customers to ensure the best results. The pandemic is another challenge for us: we adapt our services, and we are focused on continuous improvements. We stay close to our customers and we anticipate their requirements. For our customers who cannot come in our test centre, we offer the possibility to attend the testing session by live-broadcasting the crash-test so the customer feels like they are present and can have the confidence because they can follow the entire cycle from home.”

Photos: Transpolis

Impact of COVID-19 on road safety: the figures

Wolf Peter Zeplin, CEO of SMEV AG, based in Frankfurt, is more interested in Covid’s impact on modal selection than on its more short-term impact on the transport industry itself.

“In Germany, at least, the impact of Covid-19 on transport and traffic technology is rather insignificant. The industry is of course lacking from continued work and project development because of the effect of everyone working from home, which reduces efficiency of meetings and results. However, it does not have a considerable and outrageously negative effect on the ability to innovate.”

German city administrations and transport companies have, like the rest of Europe, sought to reduce the presence of vehicles in urban areas as much as possible for two main reasons, he says.

“One, reduce CO2 emissions - COVID has had no impact here. Two, reduce the last mile delivery of all goods ordered on the Internet to households with the aim of contributing further to CO2 reduction. Also this development has no direct impact from COVID.”

There is, however one observation in Germany which might be connected to the Covid pandemic, admits Zeplin. “The number of fatal traffic accidents went down by 10.6 % in 2020 compared to 2010. This was considered as a consequence of the pandemic situation because people were forced to stay at home and not to use the car. On the other hand, in Germany fatal accidents involving bicycle users increased by 16% in 2020 against 2010. This was mainly caused by the use of bicycles, pedelecs and eBikes when they do not have the necessary experience to ride them in mixed traffic situations.

The transport sector with the most growth in the last 12 months in the big German cities is the one with those battery-driven bike-sharing schemes where you can rent and drop off at any place in the city. No one considers that you need trucks and other vehicles to collect these bikes and return them to the base stations for maintenance. These trucks burn gasoline and increase CO2 emission as they keep circulating in the cities with GPS tracking to find the bikes and have their engines running for hours at a time.”

Zeplin remains unconvinced of the coronavirus’s effects on bringing about a radical change to the way that the transport sector as a whole, and not specifically the road restraint systems market, thinks about itself.

“These arguments have to be considered as weak in relation to the effects of the pandemic, even if administrations are seeking to use these arguments to drive vehicles out of our cities,” he adds. “It is purely political, with the aim to show administrative efficiency, but is it really an argument to say that the traffic technology industry have adapted to life during the pandemic? I have my doubts.”

There’s no doubt that the pandemic has made everybody think a bit differently. The transport mode we choose to get to our destination; the time we choose to travel; why we even need to go there at all. But amid all this personal and professional re-evaluation the industry whose primary goal is to keep our roads as safe as possible has embraced the changes wholeheartedly, proving once and for all that there are indeed no barriers to success.

.png?h=400&iar=0&w=1400)