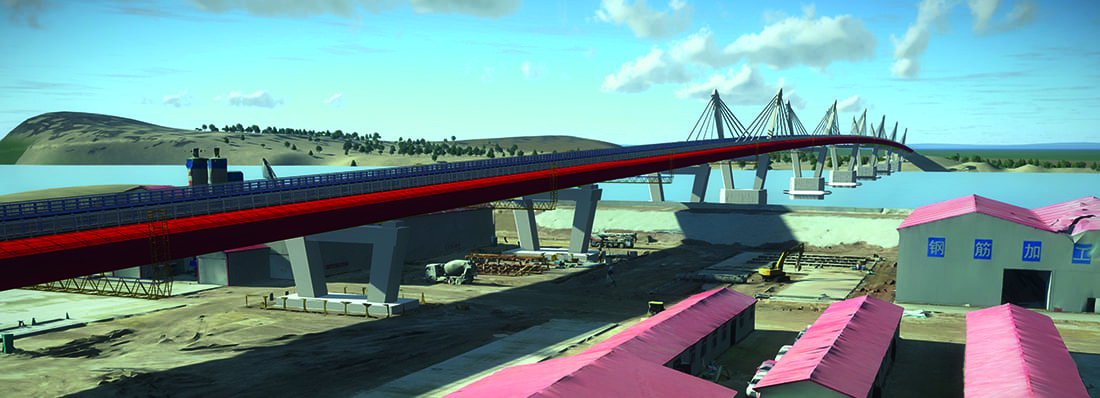

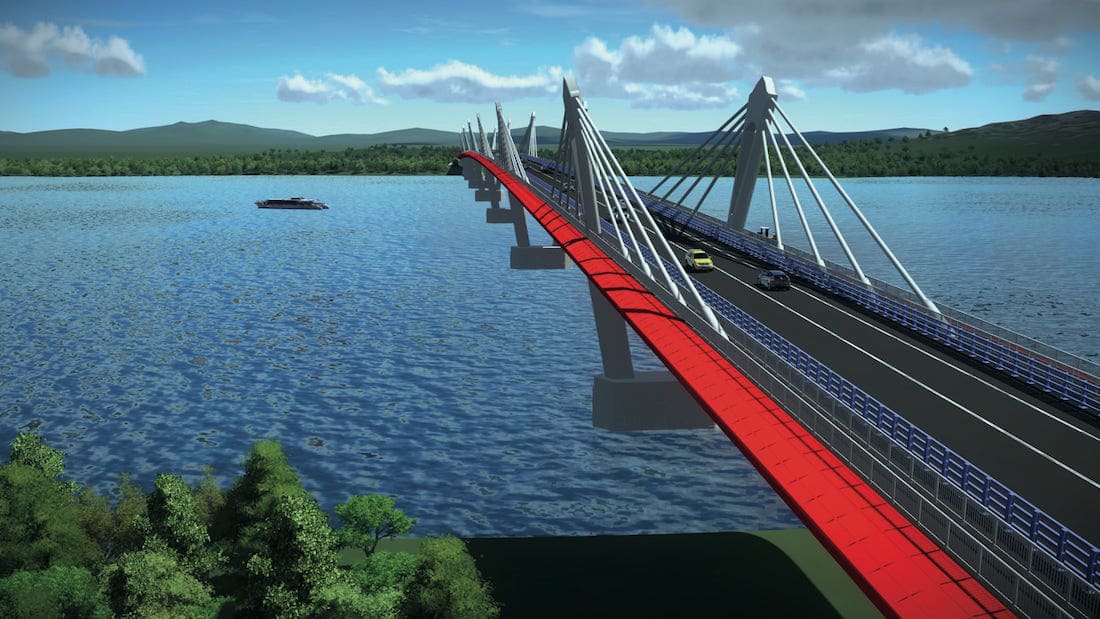

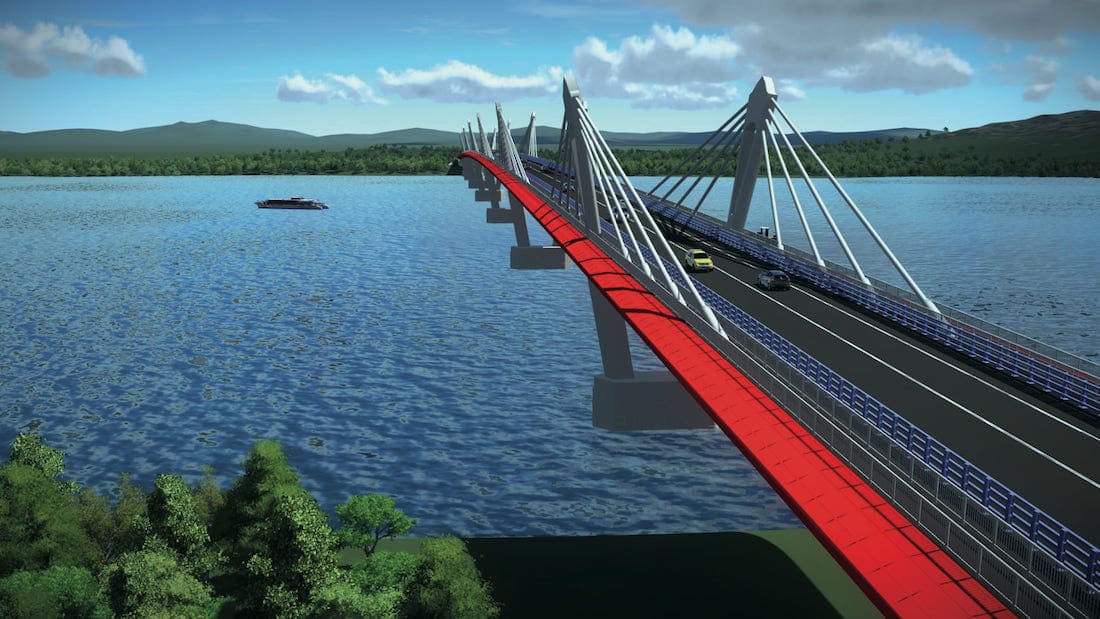

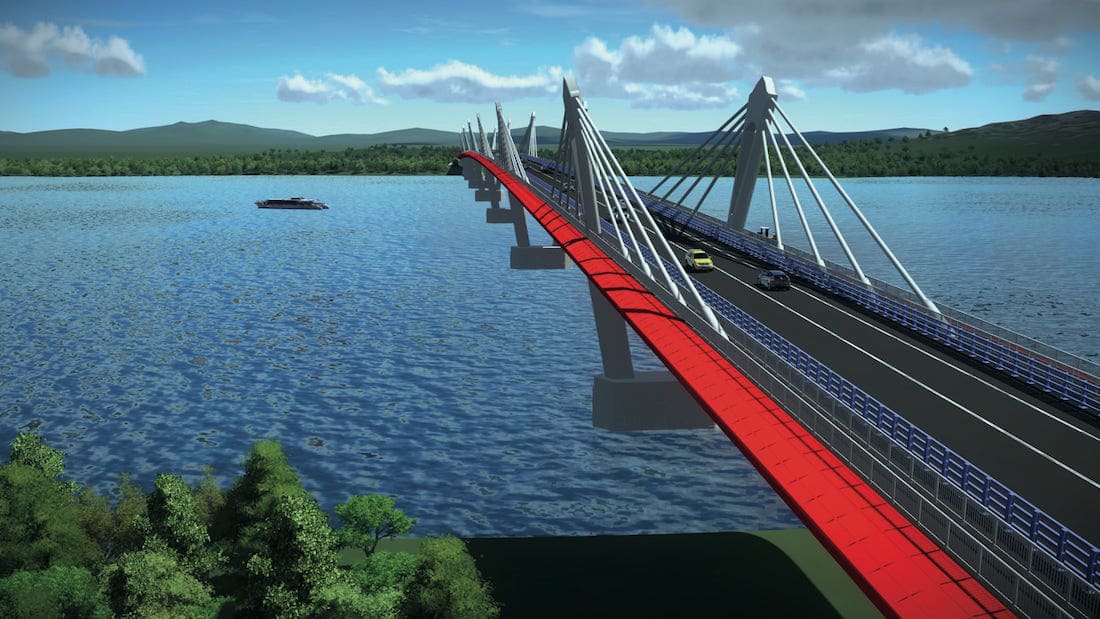

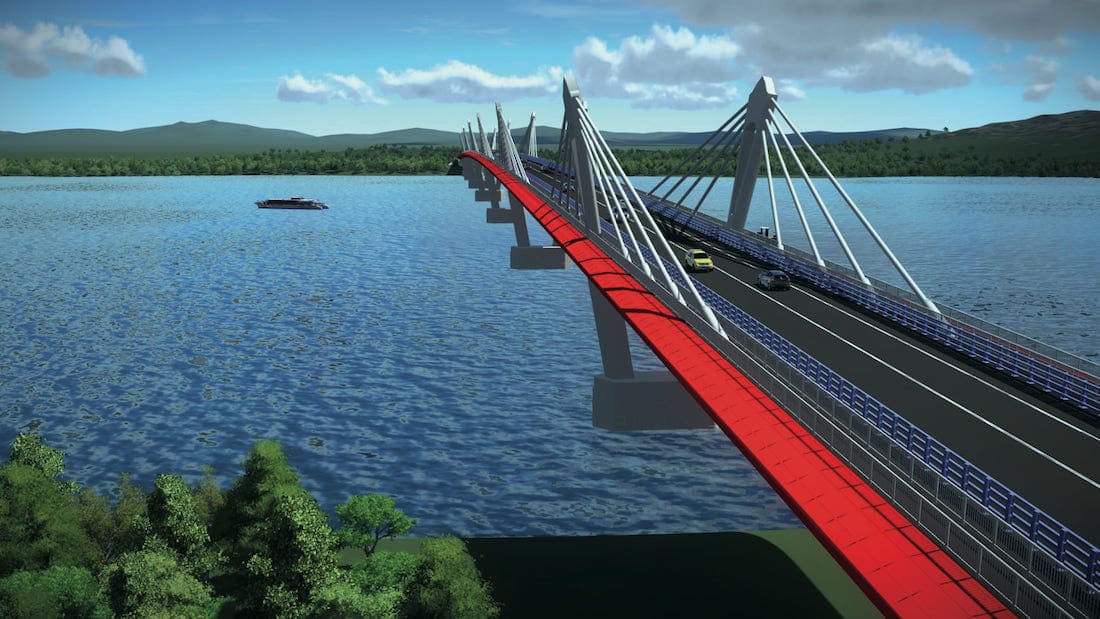

Virtual 3D models created using Building Information Modeling (BIM) techniques have been key to the planning and ongoing construction of the Heilongjiang River Road Bridge – the first road connection between Northeast China and the Russian Far East

Talk of a cross-border road bridge from China’s Heilongjiang Province to Russia’s Amur Oblast began almost three decades ago. Today, construction is underway on the US$350m Heilongjiang River Road Bridge that will connect the city of Heihe, in China, with Blagoveshchensk, Russia, creating the first highway connection between Northeast China and the Russian Far East.

The bridge will shorten the trade route to Far East Russia by 2,200 miles (3,500km), creating an important new link in the China-Mongolia-Russia Economic Corridor (part of the Silk Road Economic Belt), which is predicted to eventually increase cargo turnover tenfold.

Construction began in November 2016, with the bridge scheduled to open in October 2019. An agreement between the two nations called for China to build four miles (6.5km) of the structure, starting in Changfatun Village, a suburb of Heihe City, while Russia will build 8.3 miles (13.4km), starting in Canikulgan Village. The Russian team is also tasked with connecting the two bridge sections.

The 12.4-mile (19.9km) route will incorporate a 4,212ft (1,284m) bridge that will span the Black River Basin. This sensitive location is subject to extreme seasonal temperature variations and strict environmental protection, creating challenging conditions for construction.

To address these challenges, the contractor responsible for all civil construction, Long Jian Road & Bridge, implemented a BIM approach based on Bentley applications. ProjectWise, a Bentley-owned collaborative construction management and information sharing platform, was used to optimize project coordination.

Efficient planning stage

Long Jian Road & Bridge chose the incremental launching method for construction of the bridge, which is a low pylon, cable-stayed structure. This method can save time, money and space while minimizing disturbance of environmentally sensitive areas.

The site posed numerous obstacles to construction progress, including seasonal weather extremes, ice floes, limited channel width, and a protected river basin. To overcome the hurdles and meet the project delivery deadline, the team had to accomplish key objectives: rapidly build a bridge model within tight time constraints, create a digital environment to manage and exchange all civil design information, and define a BIM strategy that enabled the 3D monitoring of incremental bridge launching.

Long Jian Road & Bridge used Bentley’s platform for BIM-enabled construction management and trained its personnel in BIM methodologies. The goal was to meet well-defined objectives in terms of cost, quality and safety, while reducing material waste, deploying machinery effectively, and using manpower efficiently.

The project team researched and developed standardized 3D design modeling methods that enabled its members to collaborate effectively. The design team used OpenBridge Modeler software, which has 3D parametric modeling capabilities,

to achieve the required degree of accuracy for the bridge’s superstructure. The integration between OpenBridge Modeler and OpenRoads modeling software enabled precise positioning of the substructure and customization of more than 60 structures. As a result, the efficiency was 50% better than when using traditional methods.

ProjectWise enhanced collaboration and coordination among the different disciplines involved in the construction, creating a common data environment that allowed all participants to share, review and update information in real time. This collaboration accelerated decision making among management teams.

The project team also used visualization capabilities to communicate complex working procedures and to provide visual data. iModels, 3D PDFs, printing, construction simulations and virtual reality applications improved understanding of design intent, project progress and desired outcomes. These capabilities were especially helpful when communicating with the many levels of management on each side of the China-Russia border. The visualization technology for technical project management reduced time spent in meetings and on inspections and increased quality assurance. With fewer conflicts, construction progressed on schedule.

Measurable returns

BIM workflows allowed the management team to perform 25% more efficiently than when using traditional methods. The Long Jian Road & Bridge team also achieved benefits at each stage of the project, using 3D models to inform optimal material quantity calculations, and efficient deployment of personnel and machines, which reduced rework and costs.

Careful site planning reduced the construction area by 6,674ft2 (620m2), making a smaller footprint in the sensitive river basin. The project team reduced overall land use for the bridge and civil infrastructure by 8,300ft2 (770m2), saving an estimated US$14,500.

Bentley’s parametric modeling capabilities conserved engineering resources by reducing errors and rework. Construction coordination and inspection has so far taken about 30% less time than predicted. Calculating material quantities with software applications ensured that procurement was supplied with accurate amounts. Material consumption was reduced by 30 metric tons, saving a further US$14,500 on the project.

The project’s successful progress on-site is mostly due to BIM-enabled construction management. To date, Long Jian Road & Bridge has achieved a number of critical objectives, including reducing material waste by 1%, using machinery and labor 15 times more efficiently, and keeping the cost of schedule deviations under US$73,000. Upon completion, the project team will turn over the reality model-based asset management database to the owner for use in the operation and maintenance management phase. Long Jian Road & Bridge will continue to apply BIM advancements on a company-wide basis, defining standards, processes and specifications for its future bridge projects.

Chinese officials estimate that the Heilongjiang River Road Bridge will enable the transportation of more than 3,000,000 metric tons of cargo and 1.5 million passengers per year between China and Russia. The increase over present day totals of 10 times the cargo and twice the passenger traffic will make an important contribution to China’s One Belt and One Road Initiative, serving to revitalize northeastern China.

Project summary

Adding up the benefits of BIM in critical infrastructure construction

Project objectives

• Construct a 12.4-mile (19.9km) roadway from Heihe, China, to Blagoveshchensk, Russia, with a 4,212ft (1,284m) cable-stayed bridge across the Heilongjiang (Amur) River;

• Implement a BIM platform for collaborative modeling and management of civil construction;

• Achieve real-time visual tracking and monitoring of the bridge’s incremental construction.

Bentley software used

• AECOsim Building Designer, ContextCapture, Descartes, LumenRT, MicroStation, Navigator, OpenBridge Modeler, OpenRoads, ProjectWise, ProSteel, ProStructures and RM Bridge.

Fast facts

• MicroStation and ProjectWise provided a common modeling environment for 5D construction information management and real-time collaboration;

• The bridge superstructure and 60 associated structures were precisely positioned and customized with OpenBridge Modeler;

• ContextCapture helped reduce overall land use by 770m2 (8,290ft2), minimizing the impact on the sensitive river basin environment.

ROI

• Material waste was reduced by 1%, and machinery and labor were used 15 times more efficiently than predicted;

• Cost of schedule deviations was limited to under US$73,000;

• ProjectWise software optimized coordination and improved project management efficiency by 25% over traditional methods;

• Bentley applications enabled a 30-ton reduction in material consumption, compared

with original estimations;

• Construction coordination and inspection time was 30% less than allocated.

.png?h=400&iar=0&w=1400)